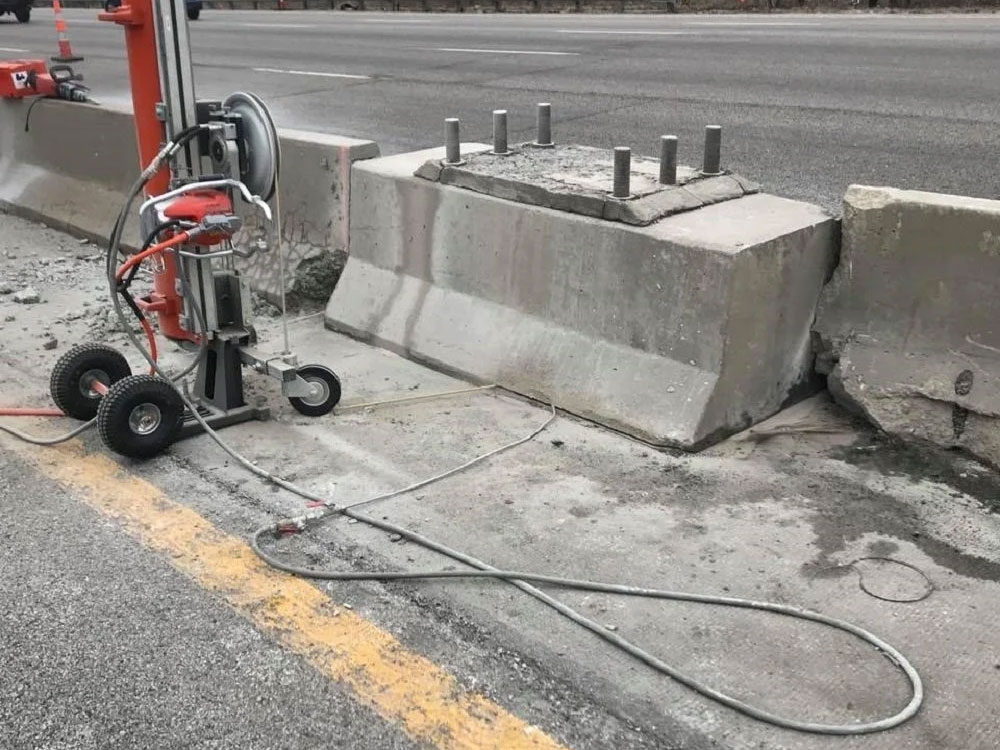

Wire saw cutting is a diamond wire cutting technique used to slice through very thick or complex concrete, steel, or stone structures. It employs a continuous loop of diamond-embedded cable (wire) that is tensioned and pulled through the material. Wire sawing is extremely versatile, capable of cutting in any orientation or shape, and is ideal for large-scale or irregular cuts where conventional saws can’t reach.

Ideal for heavily reinforced concrete thicker than 800 mm, where wall or floor saws are insufficient.

Cuts bridge piers, large columns, foundations, dams, and reactor walls.

Allows for precise sectioning of large structures for removal without using impact tools or explosives.

Frequently used in structural dismantling and retrofit projects.

Unlike blade saws, wire sawing can cut curved, sloped, or round profiles.

Ideal for circular openings, custom shapes, or angled cuts.

The flexible wire can be looped through or around hard-to-access objects.

The drive system can be set up remotely, making it perfect for tight or hazardous environments.

Cuts through concrete-encased steel, steel beams, or mixed materials without switching tools.

Used in nuclear plants, oil refineries, and industrial installations.

Wire sawing is highly effective underwater due to its non-impact, vibration-free method.

Used for offshore platforms, submerged piers, and underwater pipelines.

Diamond wire with embedded industrial diamonds

Drive pulley and flywheels

Hydraulic or electric motor

Cooling water system

Drill Access Holes: If necessary, for threading the wire through or around the material.

Loop the Wire: The diamond wire is looped through or around the cutting path.

Setup Drive & Tension: Connect the wire to a powered drive system that pulls it in a continuous motion.

Cutting Begins: The wire moves at high speed, grinding through the material while water cools and reduces dust.

Section Removal: Once cut, the section is lifted and removed using cranes or rigging.

© 2025 Rukn Alabtal Design By: sialweb